Following is a simple CimEdit configuration example. It begins with determining some information requirements for a process and continues with configuring screen for CimView that will address the information requirements.

|

Identify PLC's and points. |

|

|

Determine any required user Interaction. |

|

|

Determine the Information destinations. |

|

|

Estimate what screens are needed. |

|

|

Map out CimEdit representations to report the values. |

|

|

Select and configure CimEdit objects to meet the requirements |

Identify PLC's and Points

![]() There are three PLCs.

There are three PLCs.

|

PLC |

Connected to: |

|

1 |

Tank 1. |

|

2 |

A throttling valve regulating flow to Tank 1. |

|

3 |

Tank 2. |

![]() CIMPLICITY has the

following configured points:

CIMPLICITY has the

following configured points:

![]() Tank1_Level

Tank1_Level

![]() Tank1_Temp

Tank1_Temp

![]() Tank1_Flow

Tank1_Flow

![]() Valve_Piston

Valve_Piston

![]() Tank2_Flow

Tank2_Flow

Determine any Required User Interaction

On Viewer 1

Users need to regulate the valve piston opening through PLC 2.

Determine the Information Destinations

There are two Viewers.

CimView users need to:

On Viewer 1

Monitor the current level of Tank 1.

Monitor the current temperature of Tank 1.

Monitor the rate of flow out of the Tank 1 valve (into Tank 1).

View a Tank 1 level trend.

View a Tank 1 temperature trend.

On Viewer 3

View the percent level in Tank 2.

View the rate of flow to Tank 1.

Estimate what Screens are Needed

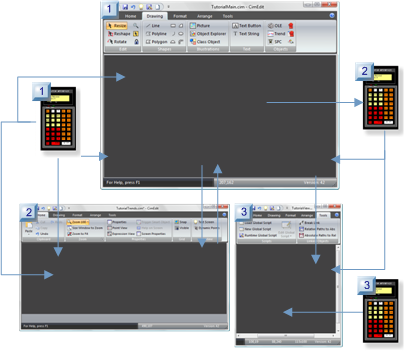

There will be three screens.

|

Screen |

Actions |

|

1 |

|

|

2 |

|

|

3 |

|

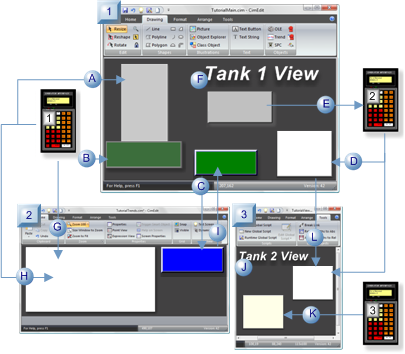

Map out CimEdit Representations to report the Values

Screen 1

|

|

CimEdit Representation |

Point |

|

A |

Fill |

Tank1_Level |

|

B |

Attribute animation |

Tank1_Temp |

|

C |

Mouse up event |

Open Screen 2 action |

|

D |

Rotation/linked object source |

Tank1_Flow |

|

E |

Setpoint/Movement |

Valve_Piston (setpoint) |

|

F |

Linked source object |

None |

Screen 2

|

|

CimEdit Representation |

Point |

|

G |

Trend |

Tank1_Temp |

|

H |

Trend |

Tank1_Level |

|

I |

Mouse up event |

Open Screen 1 action |

Screen 3

|

|

CimEdit Representation |

Point |

|

J |

Linked container |

Public variable |

|

K |

Rotation/copied object |

Tank2_Flow |

|

L |

Rotation/linked container |

Tank1_Flow |

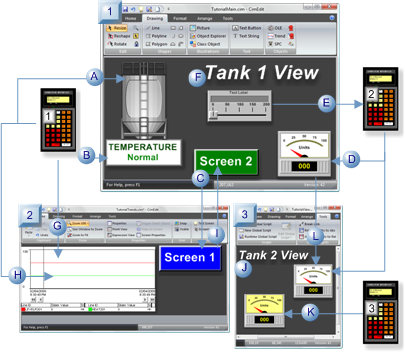

Select and Configure CimEdit Objects to Meet the Requirements

The objects are configured using some of CimEdit's powerful configuration features.

Screen 1

|

|

CimEdit Object |

CimEdit Representation |

Point |

|

A |

Tank |

Fill |

Tank1_Level |

|

B |

Text |

Attribute animation |

Tank1_Temp |

|

C |

Button |

Mouse up event |

Open Screen 2 action |

|

D |

Gauge |

Rotation/linked object source |

Tank1_Flow |

|

E |

Slider |

Setpoint/Movement |

Valve_Piston (setpoint) |

|

F |

Text |

Linked source object |

None |

Screen 2

|

|

CimEdit Object |

CimEdit Representation |

Point |

|

G |

ActiveX control |

Trend |

Tank1_Temp |

|

H |

ActiveX control |

Trend |

Tank1_Level |

|

I |

Button |

Mouse up event |

Open Screen 1 action |

Screen 3

|

|

CimEdit Object |

CimEdit Representation |

Point |

|

J |

Text |

Linked container |

Public variable |

|

K |

Gauge |

Rotation/copied object |

Tank2_Flow |

|

L |

Gauge |

Rotation/linked container |

Tank1_Flow |

|

CimEdit configuration overview. |