):

):The SPC calculations are based on the samples collected in subgroups. Each subgroup will have the same number of samples, typically 4. The subgroup size for each SPC tag is set at the SPC Tags properties form.

The number of samples in each subgroup can range from 1 to 25 inclusive.

When the number of samples in each subgroup is 1

Subgroup Mean ( ):

):

is the value of the single sample in the group, and is defined by:

Where  is the single

sample value in the subgroup.

is the single

sample value in the subgroup.

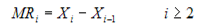

Moving Range (MR):

is the difference between successive sample values, and is defined by:

Where  is the current

sample value and

is the current

sample value and  is the previous

sample value. The number of moving ranges in the process is always

one less than the number of subgroups.

is the previous

sample value. The number of moving ranges in the process is always

one less than the number of subgroups.

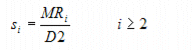

Subgroup Standard Deviation (s):

is a measure of absolute variation or dispersion. It describes how much the sample values differ from their mean, and is estimated by:

The number of subgroup standard deviations in the process is always one less than the number of subgroups.

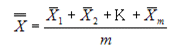

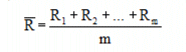

Process Average ( ):

):

Where  ,

,  , and

, and  are the

subgroup means, and m is the total number of subgroups in the

process.

are the

subgroup means, and m is the total number of subgroups in the

process.

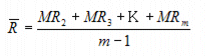

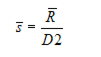

Process Range ( ):

):

Where MR2, MR3, and MRm are the subgroup moving ranges, and m is the total number of subgroups in the process.

Process Standard Deviation ( ):

):

When the number of samples in each subgroup is greater than 1

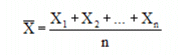

Subgroup Mean ( ):

):

is the average (not median or center) of the samples in the group, and is defined by:

Where X1, X2, and Xn are the sample values in the subgroup, and n is the total number of samples in the subgroup.

Subgroup Range (R):

is the difference between the highest and lowest samples in the group, and is defined by:

Where Xmax is the maximum sample value and Xmin is the minimum sample value in the group.

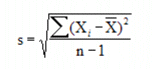

Subgroup Standard Deviation (s):

is a measure of absolute variation or dispersion. It describes how much the sample values differ from their mean, and is defined by:

Where X's are the sample values in the group,

is the group average, and n is the

number of samples in the group.

is the group average, and n is the

number of samples in the group.

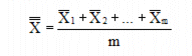

Process Average ( ):

):

Where  ,

,  , and

, and  are the

subgroup averages, and m is the total number of subgroups in the

process.

are the

subgroup averages, and m is the total number of subgroups in the

process.

Process Range ( ):

):

Where R1, R2, and Rm are the subgroup ranges, and m is the total number of subgroups in the process.

Process Standard Deviation ( ):

):

Where s1, s2 and sm are the group standard deviations, and m is the total number of groups in the process.

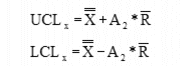

Average Control Limits (UCLx and LCLx):

Specify the approximated 3-sigma boundaries. For a normal distribution 99.74% of the samples will fall within this boundary.

Where  is the Process

Range and A2 is a constant (given in the Control Chart

Line Constants table).

is the Process

Range and A2 is a constant (given in the Control Chart

Line Constants table).

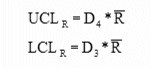

Range Control Limits (UCLR and LCLR):

Specify the approximated 3-sigma boundaries. For a normal distribution 99.74% of the samples will fall within this boundary.

Where  is the Process

Range and D3 and D4 are constants (given in

the Control Chart Line Constants table).

is the Process

Range and D3 and D4 are constants (given in

the Control Chart Line Constants table).

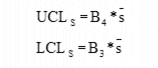

Standard Deviation Control Limits (UCLs and LCLs):

Specify the approximated 3-sigma boundaries. For a normal distribution 99.74% of the samples will fall within this boundary.

Where  is the Process

Standard Deviation and B3 and B4 are

constants given in the Control Chart Line Constants table).

is the Process

Standard Deviation and B3 and B4 are

constants given in the Control Chart Line Constants table).

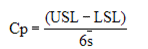

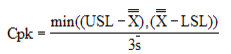

Process Capability (Cp):

Is the capability of a process to meet a specific tolerance. A process is considered capable when the percentage of samples of a variable for that process that fall within the upper and lower specification limits is greater than a specified value.

The inherent process capability is defined as:

The process capability based on worst case data is defined as:

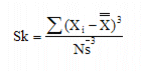

Skewness (Sk):

Is the degree of asymmetry of a frequency distribution (usually in relation to a normal distribution).

where N is the number of samples for the entire process (i.e. Subgroup Size * number of Subgroups).

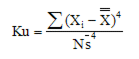

Kurtosis (Ku):

Is the degree of peakedness of a frequency distribution (usually in relation to a normal distribution).

where N is the number of samples for the entire process (i.e. Subgroup Size * number of Subgroups).