Centralization and Localization:

Reconciling apparent opposites through

Clustering

A White Paper

Presented

by:

Frost & Sullivan’s

Abstract

Through clustering, process environments can reduce the high costs associated with multiple redundancies in hardware, while still ensuring server availability. When combining sites, the clustering approach reduces the cost of control rooms as well as the manpower at those centres without compromising on close-to-process system functionality. Clustering can also be used to split sites into reliable sub-clusters to increase overall system capacity or spread system load.

About Citect

Citect is a leading, global provider of industrial automation, real-time intelligence, building automation, next generation manufacturing execution systems (MES) and on-demand benchmarking applications. Leveraging open technologies, CitectHMI/SCADA, Ampla, Nexa and Meta connect to multiple plant and business systems. Its products are complemented by Professional Services, Global Customer Support and Educational Services. Citect solutions are installed in over 80 countries and implemented in numerous industries: mining, metals, food and beverage, manufacturing, facilities, water, gas pipelines, power distribution and pharmaceuticals. Headquartered in Sydney Australia, Citect has representation in Oceania, Southeast Asia, China and Japan, North and South America, Europe, Africa and the Middle East.

www.citect.com/support

Contacts

customerservice@citect.com

Centralization and Localization:

Reconciling apparent opposites through Clustering

A perennial dilemma facing the senior management of most large process operations remains this:

- “What balance can we strike between the need for centralization and the need for localization?

- How best can we centralize operations without raising network reliability risks or losing localized system functionality?

- How can we leverage the control system most effectively even while attempting to reduce redundant hardware costs?”

Centralization: Unified monitoring and control

The ‘big picture’ view has its benefits. Companies understand this and invest significantly large monies in pulling together process data and collating it into a unified view of operations. This highlights operational status against overall performance indicators, throws up system anomalies, increases transparency across the operation and generally allows for a holistic and clear analysis of operations.

However, excessive centralization raises the risks involved in a higher reliance on the network linking the various sites. Also, achieving centralized monitoring and control has always seemed to involve a trade-off with localization.

Localization: Close-to-process monitoring and control

In typical process operations, close-to-process monitoring delivers the immediacy and granularity of process views, analysis and control that centralized control appears to sacrifice. It reduces response-time to operational contingencies and gives senior management the intangible reassurance that there is a finger on the pulse of every operational location.

However, if an organization went down the path of excessive localization of its process control and automation solutions (for example, a localized network-independent system in each site), there are many outcomes with such an architecture that are not immediately apparent: Not all process data is fed back into a central repository. In addition, each localized system, functioning like an ‘island of control’ stands the risk of going ‘out-of sync’ with localized systems at other sites.

Most importantly, there is a high cost to staffing, maintaining and upgrading such systems. Some times the high cost of hardware that comes through excessive localization means that not all locations have redundant servers. In an attempt to cut costs, some organizations seeking to achieve a disproportionate amount of localization may some times compromise on reliability by not investing in redundant servers at all locations.

Too much localization raises complexity and cost of operations to levels that may not help improve operational efficiency. Too much centralization may simplify to the point of being unrealistic.

So can these apparent opposites be reconciled?

Some organizations try to address this by getting professional services firms to write expensive custom code to combine systems or projects. In many cases, organizations achieve the objective of combining systems or projects without realizing the benefits of this unification. Worse still, an organization may invest in considerable engineering to combine stand-alone projects and at the same time create a parallel centralized project. Substantial effort and monies, but without the true benefits of clustering.

The best of both worlds: Clustering

The concept of clustering presents to Operations Managers the real possibility that the apparent contradiction between centralization and localization can indeed be resolved. In clustering ‘speak’, there is in fact, no contradiction.

To explain this, it is important to understand that not all processes – by virtue of their speed of operation or criticality – demand fully localized and dedicated control systems. For example, a water utility may be a 24/365 operation, but it clearly does not need 24/365 staffing and monitoring at all of its remote stations. Similarly, an oil and gas operation may span multiple locations, but does not necessarily require control rooms at every remote location.

Organizations that understand this and are willing to see the opportunity it presents, can and do realize significant cost savings and improved operational efficiencies.

For example, a Gas Transmission company in the United States at one time required 24-hour monitoring at each of its 20+ compressor stations. With the installation of a SCADA system from automation solutions provider Citect, the company eliminated full-time staffing at smaller compressor stations and brought down staffing to single maintenance shifts at most other stations. Currently, only one central operations centre runs 24/365. The estimated operating cost savings: over US$5 million a year.

The benefits – as illustrated above – can be considerable. However, the efforts to reduce staffing, maintenance, upgrade and hardware costs at remote locations do not have to come with a trade-off on the benefits of localization.

Clustering makes both possible.

What is Clustering?

Clustering does not mean wholesale aggregation. In very simple terms, clustering is the grouping or organization of process elements such that the association between elements of the same cluster is strong and that between elements of different clusters is weak.

In a process control environment, clustering is combining multiple SCADA systems to provide a single unified operator interface. Organizations can cluster alarms, trends, reports or I/O tags such that multiple systems that were once monitored by multiple operators can now be viewed and monitored by one operator across those systems. Clustering achieves this by working on a process-basis rather than machine-basis.

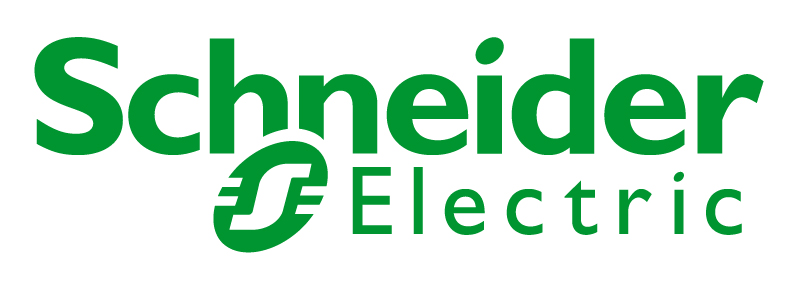

The example of a simple configuration may help. In scenario A, prior to clustering, an operation with 4 production lines might have a pair of servers for each production line (one primary and one standby server on each line). In scenario B, after clustering, one centralized server acts as standby for 4 production lines servers. This means clustering retains redundancy without the need for standby servers on each line or machine. Centralization is achieved, without compromising localization.

The benefits of Clustering

- Clustering delivers several compelling benefits:

- Reduced cost through reduced staffing at remote locations/lines/sites

- Reduced cost through a reduction in the number of control rooms

- Reduced cost through reduced hardware cost for redundant servers at each location/site/line i.e. redundancy achieved without the need for redundant servers at each site

- Reduced cost of scaling up the total system. With expansion comes increased load on the SCADA system. In a clustered system, functionality can be extended without the high costs of upgrading or replacing pairs of servers.

- Streamlined project management through improved consistency, data integrity and standardization across projects (since the centralization of clustering enables a change made in one place to be replicated across the system without the need for changes being made in every individual system).

- Potential for specialization of operators (since configuring the system on a process-basis rather than a machine-basis presents the opportunity for manpower to be focused on specific alarms, trends, reports etc across sites rather than having to view and analyze multiple process elements per machine).

These benefits can be realized across a wide range of end-use sectors; from the traditional water & wastewater utilities or oil & gas pipelines through to other sectors such as mining, metals, manufacturing, pharmaceuticals, infrastructure projects as well as building automation projects.

The Process Control Engineer of a large Australian mining operation that intends to adopt clustering has this to say about the potential benefits: “Clustering is the way we want to go. It is ideally suited to our type of operation since the site is really four or five independent zones where each zone can operate independent of the others. If we did have a network issue through fibre loss or server loss, the current configuration is such that we would not be able to get trend or alarm reports. Clustering can remedy that. Also, with clustering we will be going from a 10-server network down to around 5 servers. This halving of server cost is another significant benefit.”

Leveraging Clusters: Combining or splitting apart

Clustering is in many ways a different way of perceiving the architecture of operations.

This means that in some circumstances it can be used to combine systems, while in other circumstances it can used to actually split sites apart.

Combining: The traditional application of clustering is in combining sites or systems. By creating a single unified list of alarms across systems and a single view of trends across systems, the operator is able to act on any incidents or exceptions across systems.

In a typical operational environment, setting up such a combined environment would take anywhere between two to three weeks.

The challenge here is when there are duplicate tag, trend or event names across systems that need to be combined. That is when the degree of customization increases.

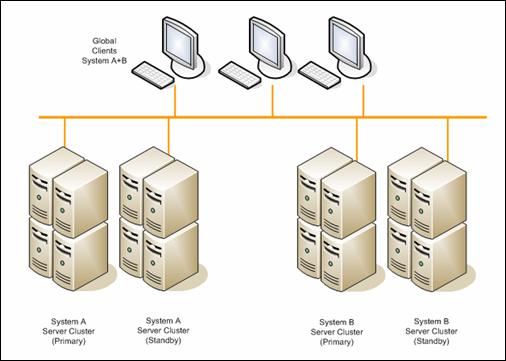

Splitting Apart: Clustering can also be used to split a system or systems to create reliable sub-systems or sub-clusters maintained through a centralized set of servers.

This approach could be used when the need is to increase overall system capacity, spread system load and still ensure that system functionality is close-to-process.

What it also does is it raises reliability levels by guaranteeing access to alarms, trends, reports or tags at each site/location. Also, in the context of expanding systems, splitting apart of the system allows users to beat the 64,000 alarms-per-cluster industry limit by putting in additional servers to the single machine.

The process for setting this up could take anywhere between 2 days to a week.

Combining Sites

Splitting Sites

Transparent Clusters

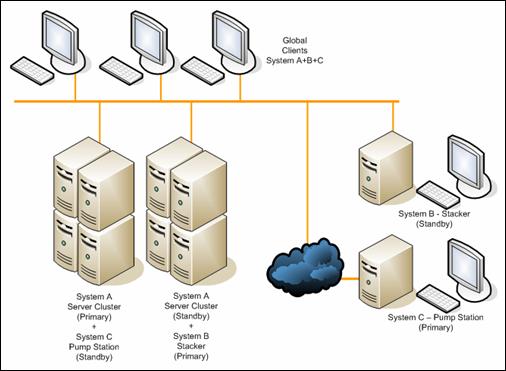

As organizations grow (in terms of increased production/processing or increased information flows), systems are expected to keep pace. This could some time involve scaling up by duplicating systems.

With a clustering approach, organizations have the ability to utilize the same configuration for a project multiple times and have the configuration automatically duplicate for each cluster. This ensures simpler and faster scaling up of systems.

It also means that once one project has been tested, duplication of this project ensures roll-out of any number of systems without having to test each of those duplicate systems. In terms of operator interface, this also means that the operator would then be able to see one display page on-screen driven by different clusters at different times based on the operator’s command. As with combining clusters, the existence of similar tag/event/trend names is a challenge in repeating projects using transparent cluster.

Duplicating Configurations for Projects

Cluster Thinking

Most established SCADA solutions providers can advise and implement clustering for process control end-users. To go about it the right way, end-users need to ask and answer the right questions:

Where in the present control architecture are the opportunities for streamlining close-to-process elements (control rooms, manpower, hardware etc) without compromising localized system functionality?

Or, on the other hand, which system presents the potential for being split apart into sub-clusters for improved capacity or more balanced system load?

- How does the proposed cluster support network fault tolerance?

- How can the issue of similar tags/trends be addressed when combining sites?

- How much of extra memory and processing power will be required?

- How easily can the proposed cluster be modified at a later date?

Clarity on such issues helps end-users maximize the benefits of clustering and SCADA solutions providers are best placed to help arrive at answers based on the operational context and business priorities of the end-user.

Most importantly, potential users of the

clustering approach need to understand how best to quantify the

potential benefits. This involves not only measuring potential

dollar savings on hardware or control rooms or manpower, but also

sizing the less tangible but equally significant benefits that come

with reconciling the need for centralization with the need for

close-to-process control.

Disclaimer

Disclaimer of All

Warranties

SCHNEIDER ELECTRIC (AUSTRALIA) PTY LTD DISCLAIMS ANY AND ALL

WARRANTIES WITH RESPECT TO SCHNEIDER ELECTRIC (AUSTRALIA) PTY LTD

PRODUCTS AND THE RELATED DOCUMENTATION, WHETHER EXPRESS OR IMPLIED,

INCLUDING SPECIFICALLY THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A GENERAL OR PARTICULAR PURPOSE. CITECTSCADA AND

THE RELATED DOCUMENTATION ARE PROVIDED "AS IS," AND YOUR COMPANY

UNDERSTANDS THAT IT ASSUMES ALL RISKS OF THEIR USE, QUALITY, AND

PERFORMANCE.

Disclaimer of

Liability

YOUR COMPANY AGREES AND ACKNOWLEDGES THAT SCHNEIDER ELECTRIC

(AUSTRALIA) PTY LTD SHALL HAVE NO LIABILITY WHATSOEVER TO YOUR

COMPANY FOR ANY PROBLEMS IN OR CAUSED BY SCHNEIDER ELECTRIC

(AUSTRALIA) PTY LTD PRODUCTS OR THE RELATED DOCUMENTATION, WHETHER

DIRECT, INDIRECT, INCIDENTAL, SPECIAL, OR CONSEQUENTIAL (INCLUDING

LOSS OF PROFITS).

Related Links

Attachments