Tuning OFS to achieve better communication performance

with the PLC

It is very important to consider the following parameters when

tuning the communication between OFS and the PLC.

Please also note that changing any of these values may result in

OFS being more loaded, and not being able to keep up with the

communication rate (and number of items) requested by the OPC

client. Careful consideration and testing should therefore be given

every time the following settings are modified.

Group min update rate: The default

value is 200ms. A rule of thumb is that the update rate that will

be set by the client for a given group should be a multiple of the

Group min update rate value in ms.

If optimised communications are required, we recommend setting

the Group min update rate to half the desired OPC subscription

rate. If it is required to have an OPC subscription rate faster

than 400ms, then we recommend decreasing the value of this

parameter. However, caution is advised as decreasing the value will

result in increasing the load on the entire system.

Sampling rate on reception: Defines

the period for checking data reception in milliseconds. Default

value is 50ms. If fast update rates are required, a value of 10ms

or 20 ms ensures good performances for heavy communication

load.

Max Channels: to achieve best

communication performance, this Alias attribute must be set to the

Number of requests per scan of the target communication module

(refer to the pdf document above)

Max Pendings: this Alias attribute

gives the max number of sent requests waiting for an answer. On an

Ethernet link, a good value is at min the Max Channels set above,

better performances can be reached with Max Pendings = 2* Max

Channels or Max Pendings = 3* Max Channels.

Note: For NOE Quantum,, it is recommended to set Max

Pending= Max Channels

Tuning on the SCADA side

The OPC client’s number of items and the requested update rate

have a direct impact on the OFS runtime.

It is useful to read the statistics shown in the kernel, and

documented in the OFSOPC driver help to get a feeling of the health

of the communications.

Below are a few common scenarios that may result in a tuning of

the ini parameters of the OFSOPC driver. It is highly recommended

that these parameters be changed by advanced users only.

[CODE]WriteLocal

parameter:

The [CODE]WriteLocal parameter controls whether the SCADA local

memory image is immediately updated when a tag is being written to

(from a page, or from cicode), or if it only gets updated on the

subsequent read. This parameter is a machine-wide setting.

Depending on the network speed and its reliability, customers

may choose to update values on the page as soon as the tag is being

written to ([CODE]WriteLocal=1), or only when it was verified that

the data was actually written to the I/O device

([CODE]WriteLocal=0).

If Fast update rates

are required (200ms and below - eg for trending):

- you will need to decrease the group minimum update rate in the

OFS configuration tool.

- In VijeoCitect/CitectSCADA, you will need to set

[OFSOPC]Group1UpdateRate to the required subscription rate.

- Finally, please decrease the IOdevice cache time. More

information is available in KB Q4950.

Intermittent

communication failures:

Comms failures may have various reasons.

If the failure is only intermittent (Unit goes online and

offline repeatedly), the first thing to check is whether OFS/the

PLC is able to keep up with the amount of data requested by the OPC

client (number of items, and update rate). As a first test, we

suggest that you increase the following ini parameter from 250 to

750.

[OFSOPC]Group1UpdateRate

This will result in decreasing the frequency of polling by OFS

to a large number of tags from PLC, and thus reducing the load on

the PLC. This may result in a stabilization of the overall

communication channel.

Secondly, if intermittent communication failures are still

experienced after increasing the Update Rate, you may try to

increase the DeviceTimeout and FrameTimeout

parameters in OFS. This will allow more time for the PLC to respond

to the requests sent by OFS. Please refer to the OFS User Manual

for further information.

More details:

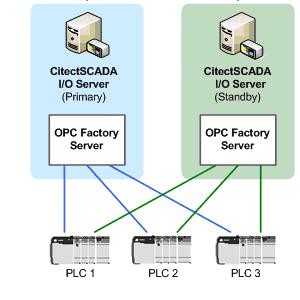

The OFSOPC Driver evaluates the Communication status between

itself and OFS by reading the Quality of the tags “#PLCQualStatus”

and “%S0”. When the quality of these two Items goes to ‘Bad’

(mainly caused by an unstable communication channel between OFS and

the PLC), then the SCADA Unit is placed Offline and

reinitialisation process starts. It could therefore be inferred

that, due to the instability of communication between the Servers

and OFS, the SCADA redundancy feature may not work as expected and

there would appear communication gaps during swithover and

switchback.