WebAccess is Human Machine Interface (HMI) software that displays real time data (and records that data) from industrial and commercial automation equipment. On the operational level, WebAccess enables control system data to be available to the operator. On the maintenance and plant management level, WebAccess allows control data to be exported to and integrated with databases.

Using a graphical user interface, WebAccess provides the following functions:

· Display dynamic process data on graphic displays, such as historical trends

· Notify operators and users of alarms and process upset conditions via an annunciator (beep), flashing colors, alarm summary display, alarm printer, pagers and email.

· Enables the operator to perform control actions, such as changing setpoints, turning equipment on or off and downloading recipes

· Executes logic using calculation tags, scripts and the scheduler for real-time "supervisory" control of setpoints

· Records historical data to disk drive, databases, scheduled logs and reports.

HMI is an acronym for Human Machine Interface. Typical HMI applications include:

1. Touch Panel Display to in an Industrial Manufacturing Facility.

Figure 1.1 - Touch-Panel HMI on Factory Floor

2. PC front-end to a semiconductor fabrication tool.

Figure 1.2 - Semiconductor Tool

3. Web browser interface to a Building Automation system to allow occupants to extend after-hours lighting.

Figure 1.3 - Building Automation Web browser for tenants

SCADA (Supervisory Control and Data Acquisition) software is used as the "front-end" to industrial control systems and building automation systems. SCADA allows Users change setpoints, react to alarms by adjusting controllers in manual or automatic mode, monitor trends, download recipes to change the product specifications these are all "supervisory" control actions performed by a person. SCADA also schedules setpoints changes automatically, turns equipment on or off on based on a schedule, or execute "scripts" that allow other supervisory control actions.

The second by second control is performed by the programmable controller (PLC), loop controller, DCS (Distributed Control system), DDC System (Direct Digital Control System), RTU (remote terminal Unit) or other automation hardware (VAV, PID Controller, etc.).

Typical SCADA Applications include:

Front-end to Distributed Control Systems (e.g. APACS, TDC3000, Net90, IA) used in oil refineries, power plants, pulp & paper mills, breweries, and continuous process industries.

Figure 1.4 - Oil Refinery Control Room

PC/PLC SCADA systems utilize Programmable Logic Controllers (Allen-Bradley PLC5, SLC500, Schneider, Modicon, GE, Omron, Yokogawa) in manufacturing facilities, water treatment plants, tank farms, and the process industries described above.

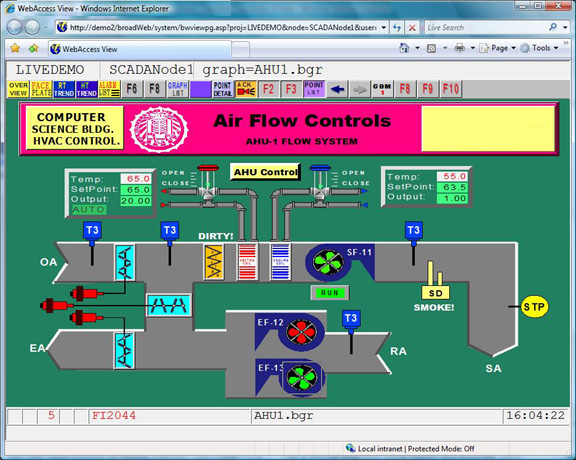

Facilities and Building Automation systems use WebAccess as the "front end" to DDC and other control systems (Echelon LON, Bacnet, Barrington, Trane, etc.). WebAccess applications include irrigation systems for golf courses, 30 story skyscrapers and university campuses.

Figure 1.5 - PC based operator interface to controls

WebAccess also records data for reports and logs, displays this data in "strip-chart" like Trends and produces reports and logs to printers and files.