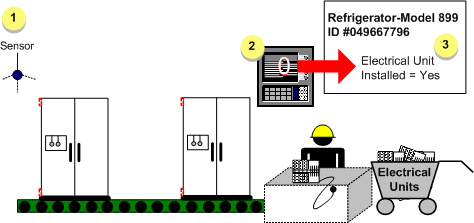

Here is an example of a point set to display at an operator's workstation in the appliance factory. When a refrigerator comes down the line on the conveyor belt, the operator reads the CimView screen that tells him if an electrical unit is required. This particular display uses text only.

|

A point set to display at an operator workstation in production. |

|

|

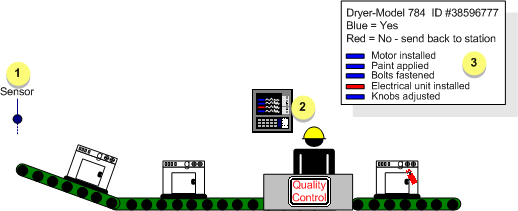

A point is set to display graphically at an operator's workstation. |

|

|

Display point list. |

Example 1. A point set to display at an operator workstation in production.

|

1 |

Sensor |

|

2 |

Point set to display at an operator's workstation. |

|

3 |

When the value is 0, the refrigerator needs an electrical unit added. |

Example 2. A point is set to display graphically at an operator's workstation.

In this example, a Quality Control station graphically displays point values. As the dryers move through the station, the operator reads the interface that is color-coded to provide information during inspection. Here, the graphic display helps the operator spot problems quickly while inspecting the unit.

|

1 |

Sensor |

|

2 |

Point set to display at an operator's workstation. |

|

3 |

Values are graphically represented in a color chart for each item on the Quality Control list. |

Example 3. Display point list.

Listed below is a sample of the factory display points.

|

Workstation |

Tracking Information |

Graphic or Text |

|

|

Main 01 |

Plant floor |

G |

Entire view of factory |

|

Main 02 |

Plant floor |

G |

Regions by service |

|

WK 01 |

Electric Unit installed Y/N |

T |

|

|

WK 02 |

Coil installed Y/N |

T |

|

|

WK 03 |

Shelving Type |

G |

Color chart |

|

QC 01 |

Installed components |

G |

Color chart |

|

QC 02 |

Final Inspection |

G |

Color chart |

|

|

|

T |

Warnings |

|

Shipping |

Send to warehouse or loading |

G |

Graphic representation |

|

Step 9. Plan display points: PRT planning. |