Welcome! WebAccess is a web browser-based software package for human-machine interfaces (HMI), and supervisory control and data acquisition (SCADA). Features of WebAccess include:

Using a standard Web-Browser (Internet Explorer 6.0, 7.0 or 8.0), users can view and control automation equipment used in manufacturing facilities, industrial process plants, and building automation systems. Data is displayed to Operators and Users in real-time with dynamically updated graphics using full motion animation. A plug-in is required for the full-animation client.

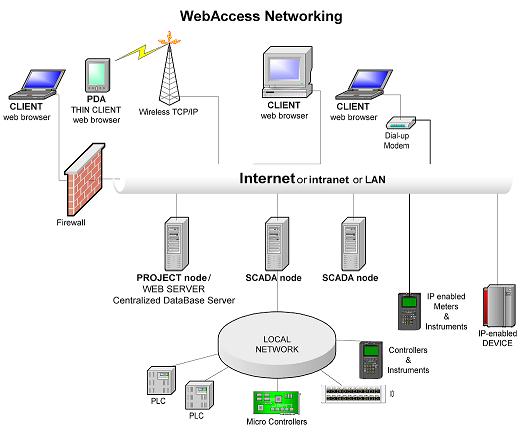

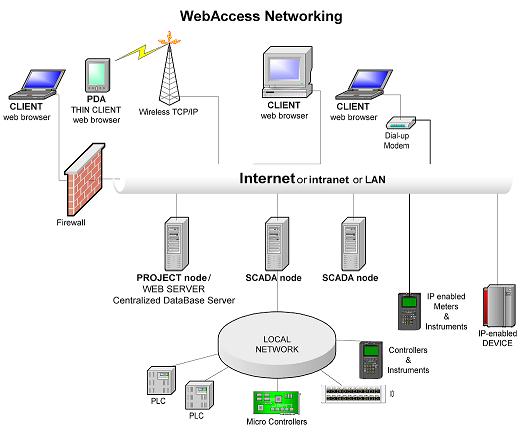

Figure 1-1 WebAccess Network: Clients, Thin Clients, SCADA Nodes and Project Node.

The unique feature, which distinguishes WebAccess from the competition, is that all engineering, database configuration, graphics building and software administration can be performed using a standard web browser as well. Engineers and Technicians can configure the WebAccess Database and Build Graphics Remotely using a standard web browser.

WebAccess uses an ordinary web server as our Project Node: Microsoft IIS (Internet Information Server) which is standard in Windows 2000 Professional and Server, Windows 2003 Server, Windows XP Professional, Windows Vista Business and Windows Vista Ultimate.

The Project Node provides the initial link between Clients and the SCADA nodes. Only the Project Node is a Web Server. Redundant Project Nodes acting as redundant Web Servers are easily implemented. SCADA nodes are not web servers (except for stand alone installations).

This makes WebAccess a "fully" web-based solution. WebAccess enables engineers, integrators and vendors with the ability to support their systems remotely over an intranet or the Internet using an ordinary web browser.

WebAccess also supplies communications drivers that enable remote personal computers to communicate with automation hardware including programmable logic controllers (PLC), IO, controllers, direct digital control systems (DDC) and distributed control systems (DCS). These drivers are easily implemented using fill-in-the-blanks forms through an ordinary web browser.

SCADA nodes run independent of any other node. Each SCADA node communicates to automation equipment using the communication drivers supplied with WebAccess. SCADA nodes also provide Alarming, Logs, Reports, Calculations and other SCADA features. Each SCADA node has its own graphics displays and a runtime database.

A Redundant SCADA node consists of primary and backup SCADA nodes. The Project Manager will download an identical run-time database to both primary and backup SCADA nodes. The Primary and backup will communicate with each other when the kernel is started, but only one will communicate to automation hardware. If the Primary fails, the Backup will begin communications to the automation devices. The Web Browser clients will be redirected to the backup if the primary node fails. Data Logging and Trending files are updated on both primary and secondary, and resynchronized when the Primary returns.

A Redundant Comport enables a redundant communications path to the Device. If communications cannot be established through primary Comport, WebAccess will try a second Comport, specified as the Backup Port. You configure the backup Port number in WebAccess, but without any devices on it. Usually the device must have two comports also. The Backup Port is usually configured as the same type. However, some Device Types allow the backup port to be another physical type; for example, Modicon Device can use a TCP/IP (network) port as a backup port to a Serial Port.

It is also possible to connect VIEW clients to SCADA nodes without a web server (although some database functions are lost). This provides an alternate path to allow remote clients to connect if a web server is unavailable.

The Project Node is a centralized database server of configuration data. A copy of the database and graphics of all SCADA nodes is kept on the Project Node. If files are lost from the SCADA node, they are easily downloaded with a single mouse click.

Remote development features accommodate large, multiple node installations, including updating of all nodes on a network from a single location or multiple locations using a web browser.

Users can be assigned various access privileges. WebAccess uses the Area of Responsibility concept to prevent changes to tags. A tag is assigned to a single Area with a change level. Users can be assigned to multiple areas with a different access level within each area. To change a value, the user must also be assigned to the same Area of Responsibility and have an access Level within that Area equal to the tags change level.

WebAccess Restricted Users can only view the displays assigned to them. Pushbuttons and other features that try to call up an unauthorized display will be blocked.

Web Access Power Users can view any display, but cannot use the engineering tool (project manager).

WebAccess Administrators are given full control and database configuration capabilities.

WebAccess Users types are independent of Windows Users.

WebAccess Client Plug-in is an Active X control that allows it to run inside an Internet Explorer 6.0, 7.0, or later web browser.

Similar in function to the full-animation client, the thin client interface provides snapshots of each display in the GIF and JPEG file formats. Values, Setpoints and Digital states are changed through a text type interface. Intended for use on a Windows CE based PDA or handheld computer; any web browser on any type of PC can view the thin client displays.

IO Tags are multi-dimensional objects that represent data read from automation equipment. Tag names can be up to 25 characters. There can be at least 60,000 tags per SCADA node and many SCADA nodes in a system or project. Tags consist of multiple fields (Tag Fields) that include Description, Hi Span, Lo Span, Alarm State, Alarm Limits, Output Limits and about 50 other qualities associated with each tag.

IO Blocks are a type of tag (our competitors call them super tags). Blocks allow multiple data values read or written from automation devices to be grouped into a single object. Blocks are most commonly used to represent PID controllers, VAVs and other multiple value "instruments" found in a control and automation systems. The typical elements of a PID block include Measurement, Setpoint and Output of the controller.

WebAccess uses vector-based graphics that provide smaller file sizes and faster downloads. Further, vector graphics provide dynamic display resolution and are continuously scalable. Displays can be run at a user-defined resolution; independent of the display resolution the graphic was built with. Engineers and technicians can develop applications in one screen resolution and users can run them at another.

The WebAccess Graphic builder provides pre-built symbol libraries including pre-animated widgets. At least 300 symbols and widgets are in the default product including pipes, valves, tanks and vessels. Users can easily add symbols and create widgets from existing scratch or tear a part exiting graphics.

AutoCAD DXF files can be imported, edited, grouped, filled and animated. They become vector elements in the graphic that can be infinitely scaled.

For flexibility, Bitmaps, JPEGs and GIFs can be imported and animated. They cannot be edited other than scaling and position. They are not converted to vectors but remain as bitmaps with all the limitations inherent in bitmap images.

Template Displays allow all tags to be viewed using one of a few templates. Pre-built templates displays are supplied with all WebAccess systems. These system displays and dialog boxes allow all Tags to be viewed and changed immediately without building a single new graphic

The Block detail displays allow a single graphic display, including animation, to be used to view all blocks tags of the same block type. This dramatically reduces time to implement a system. Additional Block Tags that are added the system a viewed instantly without building or modifying a display. Many drivers come with default block displays for commonly used block types (e.g. PID controllers, Air Handlers and VAVs). The default Analog Point Display allows all analog tags to be viewed using this one display

The engineers and technicians using DRAW can edit template displays. Template displays include Analog Point Detail, Digital Point Detail, Text Point Detail, Parameter Detail, Block Detail, Data Log Trend, Real Time Trend, Alarm Log, Action Log and Faceplate Group and Overview displays.

WebAccess provides a notification system to inform operators of process and equipment status. Each Tag in the system has alarming which can be enabled in its database configuration without creating additional tags or logic. Alarms for each tag include High-High, High, Low, Low-Low, Deviation, Rate of Change and State alarming. Deadbands are provided for analog alarms. Features include Alarm Summary of Current Alarms, alarm filtering, alarm priority, alarm sorting, an Alarm Log of all past alarms, alarm limits adjustable in run-time, temporary alarm disable, alarm horn, alarm status on all displays and an Alarm Graphic for each tag in the system to help operators quickly find the appropriate display and correct the alarm.

Pager and Email notification of Alarms is a standard feature in WebAccess. No third party software is required. Tags can be individually selected to generate an email, assigned recipient email address or use global email recipients. The scheduler can schedule different email recipients based on Time of day, shift, Day of Week, and Holiday schedules.

Each tag can be logged to a separate file on the SCADA node hard drive. Historical and Real-time data for the tag are viewed in the Data Log Trend displays. The traditional strip-chart trending format includes a horizontal time line, with time stamping, multiple scales for each tag and a cross-hair pointer to read pinpoint data. Up to 12 tags can be viewed at a time (using a single window). Tags can be added or removed from the Data Log Trend group without losing historical data. X-Y plots are also available with a single mouse click. Scrolling through time and changing scales of displayed data are also standard features.

Real-Time only trending is supported for trends of short-term data that does not need to be archived. Examples include tuning parameters for controllers or other seldom viewed information. Real-time Only trends are also useful for Panel type interfaces or devices where disk space is a premium. Real-time Only trends loose data once it scrolls off the screen or the display is closed.

System development is made easier and faster by utilizing the standard Dialog Boxes for user interaction. These boxes are pre-built and popup when a user tries to change a tag (Change Dialog Boxes, one for Analog, Digital and Text tags) or request a display list (User Built Displays, Trend Displays, Data Log Trend Displays, Overview Displays, Faceplate Displays and Alarm Groups.

The standard change dialog box provides the ability to enter data without a keyboard using numeric buttons (for analog tags), alpha numeric (for text type displays) and state buttons (for digitals with appropriate state descriptor. This is especially useful for field mounted display panels using a touch screen instead of a keyboard. This also speeds system development for users of touch screen only applications and provides a backup for keyboard users.

Standard feature in WebAccess Client is a Tag Browser. This is a Windows Pop-up Dialog Box. It shows all tags in the system. The can be filtered by Tag Type, IO Channel.

The Tag browser also provides a "Point GOTO" feature that shows all points in the system where the tag is displayed including all user built graphics, trends, alarm summary, Detail Displays, etc. With one click you can got to that display. The Point GOTO feature provides Tag cross-referencing of tags and displays in the run-time VIEW.

Scripts and Displays support the use of local screen tags to store results, read operator inputs and create complex calculations with screen scripts. By using local screen tags in Scripts and Displays, you do not decrease your licensed tag count. There is no limit to the local screen tags in WebAccess.

Calculation Tags, Accumulation Tags and Constant Tags are globally available. Calculation tags provide arithmetic and logic calculations, similar to a programmable calculator that runs repeatedly using inputs from other IO tags. Accumulation Tags are Totalizers or Integrators (e.g. totalize flow from flow rate). Constant tags are holder tags used for operator entry or to display the results of a script. Calculation, Constant and Accumulation Tags are limited to a number equal to your IO tag count limit (e.g. if you have a 1200 tag limit, you have 1200 IO tags plus 1200 Local Tags = 2400 tags)

Data Transfer provides an easy to implement method of sending data between automation equipment. The Data Transfer reads a tag then sends the value to another tag on a periodic frequency. A deadband can be specified to minimize unnecessary communication and send changes to the source tag.

Scripts in WebAccess are based on the open source programming language, Tcl, or the script languages used on many web sites: JScript and VB Script.

Web Access supports version 8.4 built-in Tcl commands and features and installs a Tcl script engine as part of the client plug-in.

WebAccess uses the JScript and VB Script engine provided as part of the Microsoft Operating system on the SCADA Node and clients.

Scripts are simple programs used to customize your displays screens and SCADA system with user-built calculations and logic. Scripts in WebAccess are powerful enough to communicate with other programs, create reports and do control.

If you have any programming experience, you can be writing scripts in 30 minutes. Tcl is an industry standard taught in many schools. You can download Tcl programs and tutorials from the Internet.

For advanced users, WebAccess provides Application programming interfaces (API) to the SCADA node and to the VIEW client for Visual C, Visual Basic, C# (C Sharp), JScript and VB Script.

Vector Graphics allow users to zoom in to magnify any display up to a power of 8x (800 %).

WebAccess local SCADA node supports a non-web browser version intended for standalone architecture and control room type users. Multiple display windows can be opened with a single mouse click. Users can save multiple windows, size, position and default display as a display group, then re-open this group from a menu list or pushbutton. Other features of display groups include hide menu bar, no resize and exit password level to close WebAccess.

Default Navigation Toolbars ensure every display has Navigation, Alarm Handling and Point Access controls. The default toolbars can be modified or new toolbars built using symbols, flashing colors and pushbutton keymacro commands. Right Click Menus enable similar functions as the default toolbars.

Pushbutton Key Macro Commands provide standard control and monitoring features with a single click including alarm acknowledgment, display navigation. Many Key Macros have equivalent Keyboard Function Keys that allow Web Access VIEW to be deployed on systems without a mouse or touch screen.

Display-scan tags are scanned only when an operator calls up the display. These are usually setpoint, controller tuning and controller configuration" tags in the controller (i.e. tags that don't change very often and are used infrequently). By using Display Scan type tags for setpoint, tuning and infrequently used, "non-alarm points" and "not data logged points" you can effectively increase the throughput of your system.

WebAccess can scan as fast as once every 100 milliseconds (ten times per second). Entering a 0 for scan time, WebAccess will try as fast as possible. The actual speed depends on the automation device.

WebAccess provides many Native Drivers that communicate directly to PLCs, devices and automation networks without using 3rd Party Servers (like DDE Servers) to provide faster and more reliable communications.

There is no charge for a Client license. This includes VIEW clients that can view and control in real-time and DRAW, which allows users to build new graphics and configure a database

Any WebAccess system can be copied to another PC and used for off line development. Every engineer and technician can have is own system on a laptop for off-line testing and development.

Any WebAccess system can be copied to another PC and used for Simulation and Training. Every student can have is own system on a laptop for off-line training. Tags will initially be set to 50% of SPAN, but can be changed and the new values held. Alarms will occur; Alarm Logging and all features are enabled except communications including the device drivers, DDE and 3rd Party API interfaces. The node will run for 2 hours.

Recipes provide an easy method for operators and users to change the value of hundreds of settings in automation devices. Start-up or Shutdown settings can be downloaded from a single pushbutton and the "recipes" for various products can be used to "set-up" automation equipment for different product runs of multiple products.

Data can easily be exchanged between automation devices using the Data Transfer function. This is especially useful when data needs to be exchanged between automation devices that use different communications protocols (which can't communicate directly) or with "single master" protocols.

Dynamic Data Exchange (DDE) and NetDDE utilize the Microsoft communications standard to exchange data between your automation equipment and 3rd Party software packages. WebAccess acts as both a DDE Server and a DDE Client to interface with spreadsheets, Paging Software and any software that supports DDE.

A generic DDE Device driver allows any DDE Server based, 3rd Party Device Driver to be used with WebAccess SCADA node. Dynamic Data Exchange (DDE) and NetDDE utilize the Microsoft communications standard to exchange data between your automation equipment and 3rd Party software packages. Many Automation Vendors supply DDE Server based device drivers that you can use with WebAccess if there is not a Genuine WebAccess Driver available.

WebAccess provides interfaces to web-enabled Video cameras allowing operators and users to monitor equipment and facilities using the WebAccess client. Live full-motion Video cameras, audio and Windows Media are viewed in same Graphic display as Trends, Alarms, Pushbuttons and Live Data.

The Scheduler provides control and setpoint changes based on time and date. Lights, Fans, and HVAC equipment are turned on and off based on the time, day of week and date. The Scheduler is also used in process control and manufacturing applications. The Scheduler can be modified and downloaded by Project Users from the Project Manager and by Power Users from VIEW.

Pagers, wireless PCS and Cell Phones that can receive text messages can also be used for notification of Alarms and events. No third party software is required. Tags can be individually selected to generate an email message to a specific recipient address or use global recipients. The pager or wireless PCS must be able receive emails (a standard feature with Skytel and most Pager services).

Email notification of Alarms is a standard feature in WebAccess. No third party software is required. Tags can be individually selected to generate an email, assigned recipient email address or use global email recipients. Alarms can be acknowledged via a reply email.

The scheduler can schedule different email recipients based on Time of day, shift, Day of Week, and Holiday schedules.

WebAccess can email reports and logs generated with Scripts and Pushbutton Keymacros.

Standard Microsoft Icon files (*.ico) can be added to user built tool bars. These can be imported from any application. Toolbars can also be customized with animation using BBN files built in DRAW to provide flashing, color change, text changes or any animation.

WebAccess allows you to import Nodes, Tags, Graphics, Scripts, Keymacro files and entire databases from a remote node. This allows you to "Merge" projects by importing to an existing project or the "Split" projects by importing into a new project. This can be down remotely over the Internet or intranet to allow field personnel to get the latest version of a project database or graphics from the Home office.

The database export and import to EXCEL allow users to create and modify Tags and Blocks in a spreadsheet using copy, paste, edit and other EXCEL tools. Databases can be imported from other HMI packages. Tags and Nodes can be imported from other WebAccess Projects to allow aggregation of multiple facilities into a larger Project or to scale down and make a node independent.

WebAccess will log real time data, operator actions and other system logs to ODBC databases including SQL Server, Oracle, MySQL and Access. Microsoft Access databases are provided as the default. WebAccess script also provide SQL queried to read, write and manipulate these ODBC databases.

Monitor who connects to the project and SCADA nodes with web browser using the System Log.

Generate HTML Reports using menu-based queries of Centralized ODBC Logs based on Date, Time, Tag, Node including:

· Analog Tag Log

· Discrete Tag Log

· System Log

· Alarm Log

· Action Log

Copy and paste these html reports to EXCEL, Word, etc.

Scheduled Reports include Shift, Daily and Monthly reports that are automatically generated from the Real-time data. Users & Operators can View the current and previous reports using a web browser. The output of the Scheduled Reports can be copied and pasted into EXCEL, WORD, and other general-purpose office applications as a formatted table or spreadsheet

The WebAccess SCADA node emails scheduled Reports to users, managers, accountants and engineers. The output of the Scheduled Reports can be copied and pasted into EXCEL, WORD, and other general-purpose office applications as a formatted table or spreadsheet.

Text-to-Speech technology Annunciates alarms locally on the SCADA node. No recording is required by the user. A sound card and speaker is required. A choice of male and female voices reads the Tag name, description, Alarm Type, Alarm Limit and Alarm Value.

WebAccess will archive data to network folders, zip drives or other drives and will delete old data from the on-line Data Log Trend and ODBC Log files. This "file maintenance” feature prevents files from growing too large and provides archiving of important data.

Email notification of Alarms is a standard feature in WebAccess. No third party software is required. Tags can be individually selected to generate an email, assigned recipient email address or use global email recipients. Alarms can be acknowledged via a reply email.

With the appropriate security code, emails can be read from a POP3 account by the SCADA Node, and the action commands and built-in Tcl will be run as a script. Setpoints can be changed, Status changes, messages sent to operators and reports.